A Storybook History...

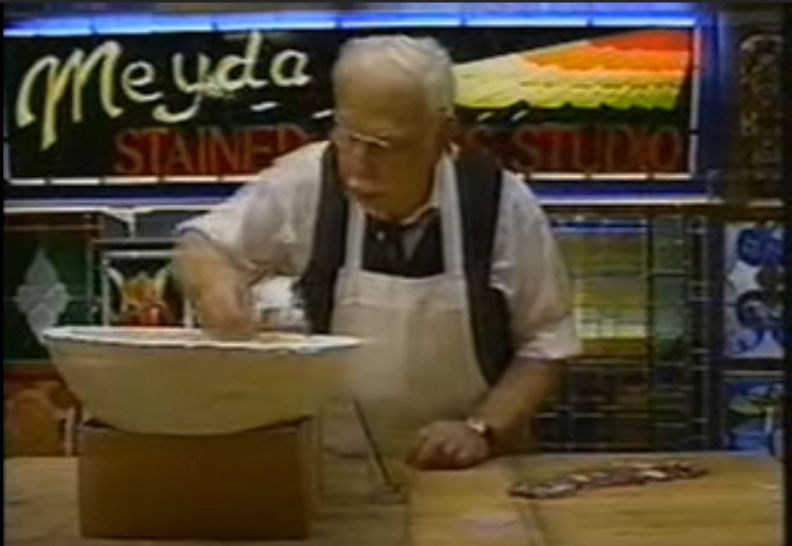

Meyda Tiffany Lighting was founded when Meyer Cohen was asked by his wife Ida, to build a stained glass window in their kitchen so they wouldn't have to view the vintage cars in their neighbor's driveway. Meyer was a master craftsman and inventor, his wife Ida, was a natural business woman - together they combined their names to form the Meyda Lighting Brand we know today. What began as a hobby evolved into America's Premier decorative lighting manufacturing and importing company.

Today Meyda Lighting continues to operate as a family-run business, with the Cohens' son, Robert, at the helm and grandsons Chester, Max and Ben by his side. The company was founded on a Do it yourself philosophy. This spirit has led the company’s strategy of in-sourcing technology, absorbing competitors and buying vendors. Over the years, the Meyda family of Lighting companies has evolved and is based in the 180,000 square-foot headquarters and manufacturing facility in Yorkville, New York.

Meyda Lighting has created the world’s most prolific collection of stained glass lamps, fixtures and windows including Tiffany reproductions and Meyda original stained glass designs using our famous copperfoil construction. Each is a unique work of art for generations to cherish for many years to come. Some were featured on popular TV shows such as “How It’s Made,” “The Price is Right,” “True Blood,” and “ABC’s Extreme Makeover.” Currently hundreds of in-stock Tiffanies and other stained glass designs are available with a one-day lead time. Our stained glass collection includes Arts & Crafts and Mission lighting that honor the rich tradition of minimalist design and quality craftsmanship. Straight lines and geometric designs highlight the best and brightest in this group.

The crowning touch for any Meyda Lighting decorative piece is the finish, and when it comes to the finish, process is everything. Over the years, we have developed a myriad of meticulous finishing techniques. Additionally we’ve purchased state of the art application equipment and invested in technologies. Create a poetical fusion for fixture details and surfaces with the rich hues, depth, sheen and character of mottled wet paints brushed by artisans and the consistent durability of environmentally friendly, scratch and chemical resistant powder coat.

Additional innovative processes include: color blending/replicating, sand carved etching, electroplating, anodizing, burnishing, museum grade clear and tinted waxing, dyeing, reverse painting, grinding, abrading, cutting, faux wood, antiquing, and natural aging, as well as high polished, hand-buffed and chemical patinas for specular reflection or a satin look.

Protective marine grade and UV/corrosion resistant exterior finishes are available to withstand the harshest climates. We have the ability to meet the most discerning client needs and provide value added techniques for volume conscious purchasers. With hundreds of hand-applied finish options to choose from, Meyda Lighting offers an extensive palette of rich tones and textures to reflect individual tastes, sensibilities and lifestyles.

Meyda Custom Lighting was launched during the building of the world’s largest freestanding LED chandelier, which is a centerpiece of the Stanley Theatre in Utica, New York. The massive chandelier is 35 feet wide, 11 feet tall, weighs over 3 tons, and was created using advanced technology and artisanship employed by the division. Not just limited to one of a kind pieces, Meyda Custom Lighting provides scores of themes for various projects across a range of market segments. No project is too large or complex. An example of these efforts is the award-winning Chandel-Air series which integrates innovative custom lighting designs and ceiling fans with lamping and control options to achieve up to five layers of light from a single fixture.

In 2009, Meyda Lighting acquired a key competitor, 2nd Ave Lighting. Founded in 1979, 2nd Ave offers American-made custom and customizable chandeliers, pendants, lanterns, street lamps and other fixtures. Distributed primarily to the hospitality design community, this division manufactures upscale bespoke lighting with an emphasis on hand applied premium finishes, diffuser styles, and lens materials. Scale and proportion are optimized with luminance by integrating impeccable designs to meet clients’ aesthetic vision and functional requirements, whether it’s a one-of-a-kind masterpiece or a complete theme.

Quality Bent Glass opened its doors at the turn of the 20th century. The company revolutionized the manufacturing process for high temperature glass forming by custom building production capacity glass forming ovens and kilns. Quality Bent Glass is best known for supplying fixtures and components to the original Louis C Tiffany Studios. The Quality Bent Glass division was a vendor for Meyda Lighting for many years, eventually becoming an early acquisition of Meyda Lighting. We are one of the only remaining manufacturers of bent glass lighting and take pride in a rich heritage and rely on the expertise of over 100 years in the making. We are still creating timeless masterpieces using original tools, technologies and techniques. Quality Bent Glass is credited with producing the original Coca-Cola stained glass lamps which are still made today. High-fired glass designs and metal finishes are customizable as each Meyda Tiffany bent glass lamp or fixture is handcrafted to order. The division also creates the Revival, Gas & Electric and Schoolhouse Glass collection.

To meet your exterior lighting needs, our Build Your Own Craftsman Signature Series features Brass and Copper fixtures with unlimited combinations of styles, functions, sizes and finishes. Outdoor sconces, lanterns, pier and post mounts and deck lights are also available. Crafted of Marine grade materials like brass and copper, timeless living finishes are offered to endure harsh climates.

The Fused Glass Collection was a natural product addition given our long standing expertise in hot glass fabrication techniques mastered in our Quality Bent Glass division. Traditional workmanship, high fire kilns and original tools are used to slump and fuse glass in the old world tradition. Pendants, sconces and other fixtures feature unique glass textures and stunning color/design combinations. Sinks and countertops are extreme examples of these custom capabilities.